How To Make Copper Ring Blanks

/A lot of you have been asking me how I make my ring blanks over the past year so I wanted to tackle that this week. It's actually quite simple and requires minimal tools so it's something you can start doing right away.

*This post contains some affiliate links, which means I may receive a small commission if you click on or purchase from certain links listed. This is how I'm able to run this blog, share my knowledge, at no cost to you. Many of the products recommended in this post are products I personally use and love. Thanks for supporting Maker Monologues!

The tools I use for making ring blanks are:

Copper wire (I now use 18g)

Big wire snips (similar here)

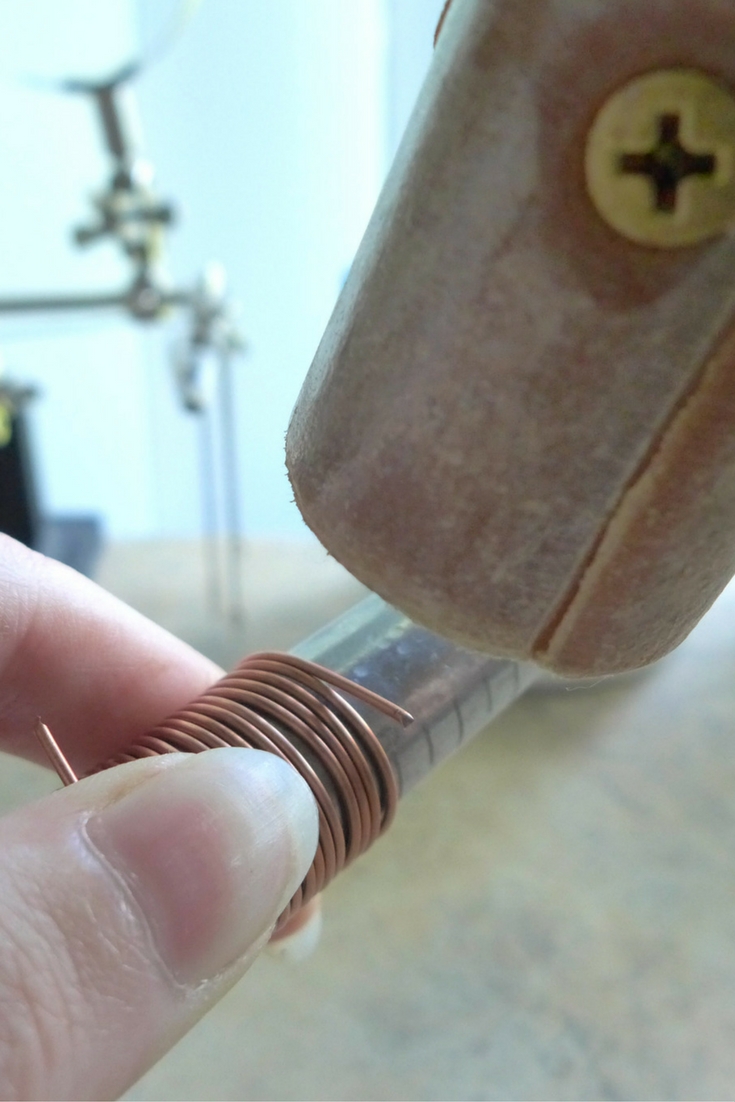

First, you're going to take your wire, cut the length you need (or don't cut a piece if you want to wrap wire straight from your spool). You're going to hold your ring mandrel in your left hand (if you're right hand dominant or vice versa). Hold the end of the wire down with your thumb while holding the ring mandrel. Then, with your other hand, you're going to start to wrap the wire around your ring mandrel.

Wrap the mandrel as far as you'd like to make as many copper ring blanks as you'd like. Once you're finished wrapping take your wire snips and cut the end of your spiral. You want to hold onto the wire tightly because if you let loose the wire will unravel a bit and get all loose which makes hammering the ends down more difficult.

Both ends of your wrap will not be uniform to the spiral so take your rawhide mallet and hammer down each end so it's flush with the rest of the spiral. Slide the spiral off your ring mandrel. Keep in mind that your spiral (your copper ring blanks) will be several sizes bigger once you let it loose. So if you're trying to make ring blanks from sizes 5-7 start your spiral at around 6 and go down from there. Also, different wire gauges may cling tighter so always test it out.

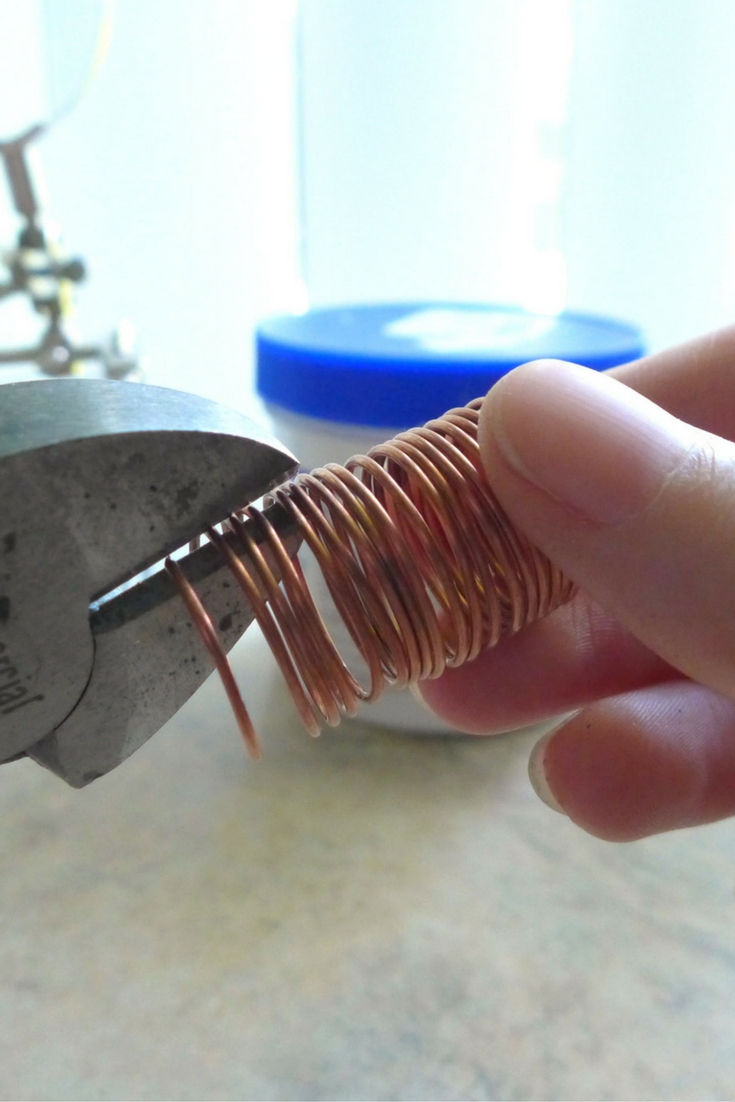

Next, take your big wire snips and start snipping the spiral vertically creating individual copper ring blanks. That's really all there is to it. You can usually snip about 5-6 rings at once depending on the wire snips you use, which is why I don't recommend using your smaller wire snips for this unless you want to cut one at a time.

What you may now be wondering is how to make your ring blanks straight, without bumps and warps.

Take a steel block (I'm using the anvil that came with my bench pin -- I highly recommend this bench pin, I find I use mine daily), and with your rawhide mallet hammer down any bumps you see, do this for each ring blank. Flip the ring blank over and do the same on the other side. Simple as that. If you have 2 steel blocks and put the ring blank in between them it would only take a couple of strikes of the hammer to get all the bumps out but I have yet to invest in those.

I do not solder my ring blanks before using it to electroform because the electroforming process is much like soldering. If you can get a crystal to form to a ring blank without soldering then you can certainly go without soldering your ring blanks closed. It will take up less time and energy.

That's all there is to forging your own copper ring blanks (or whatever metal you're using). Now that you've got a bunch of ring blank what to do with them?

You can try this,

or this,

or maybe this looks fun!

Enjoy!

Was this helpful for you? Do you have your own way of creating ring blanks? Let me know in the comments!